A game changer in plastic recycling

We are an innovative cleantech company focused on converting plastic waste into valuable products through low-carbon chemical recycling on an industrial scale.

Pioneering plastic circularity

Most plastic waste is either incinerated or ends up in a landfill: globally, less than 20% of plastic produced gets recycled. More and more people are expressing their concerns about plastic pollution, and governments, companies and consumers are taking action.

Pryme seeks to contribute to a meaningful solution to the global plastic waste problem by enabling the circularity of plastic. We convert plastic waste into valuable petrochemical products using a proven pyrolysis process that is enhanced with proprietary characteristics and has a low carbon footprint.

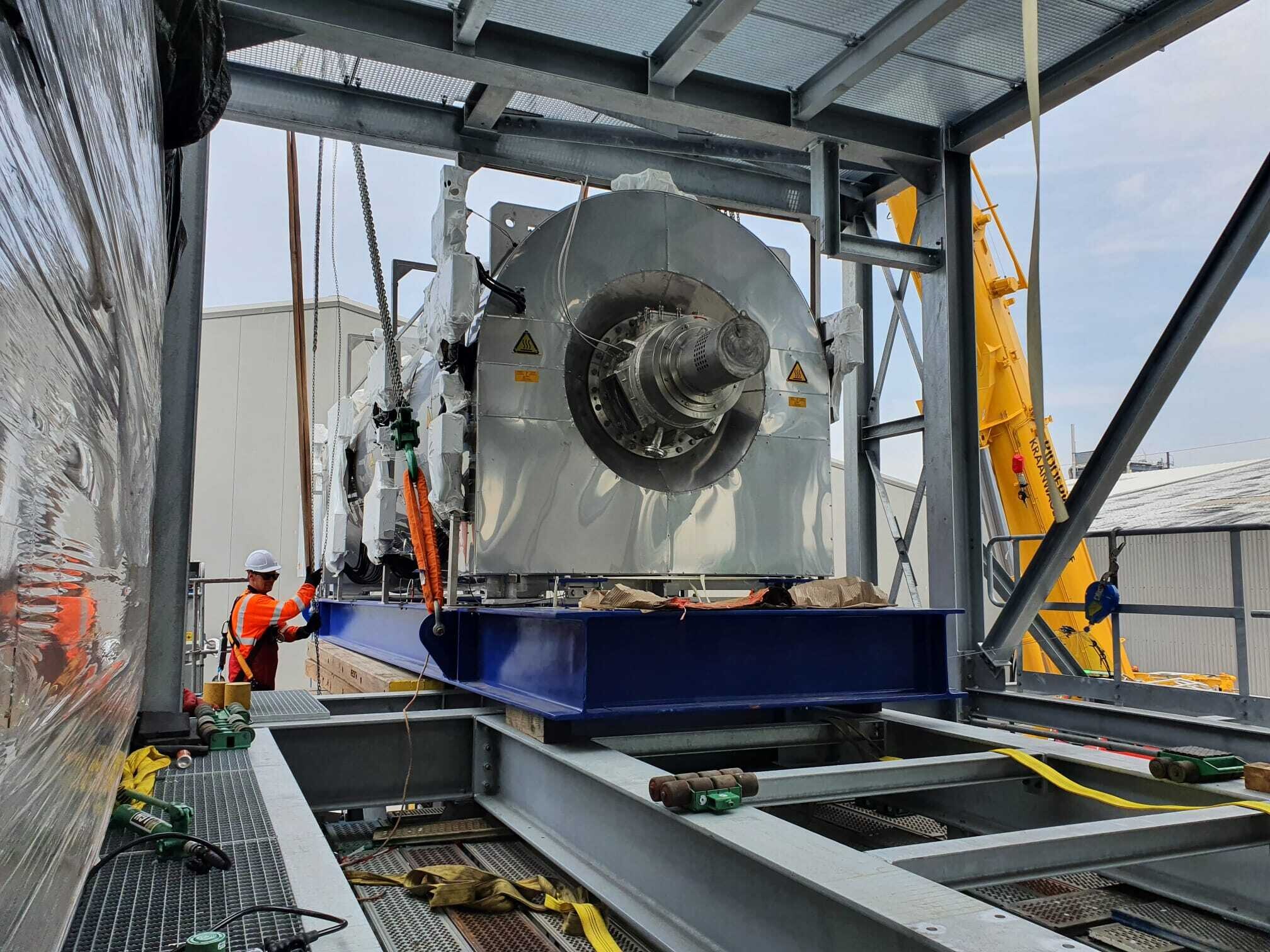

Our first plant in Rotterdam will start production in 2023. Once it is operational, we will begin an ambitious roll-out process to realize the enormous potential of our technology through a combination of owned-operated plants and licensing to strategic partners.

13+ years of recycling-focused R&D

Pryme’s roots go back to 2008, when our founder, Johannes van der Endt, invested in an industrial process that converts waste into useful material. After many years of research, the company has developed an efficient and reliable technology capable of transforming large quantities of plastic waste into petrochemical products.

Research

Start research on reactors and feedstock

First tests

First lab tests with 5L reactor and with feedstock

Pilot setup and testing

Wind down due to low oil prices

first industrial-scale plant

Engineering and permitting of first industrial-scale plant in Rotterdam

Start construction

Capital raise and start construction of first plan

Start of production

Start of production of first plant

Governance

Please find the outline of our organisation & legal structure below.

Experienced, professional team

An ambitious team of professionals with many years of experience in the industrial sector has laid the foundations of our company. New appointments are underway to consolidate our foundations and help steer our business forward.

Christopher Hervé

CEO

Pascal Spiekerman

COO

Dominique Gemoets

CTO

Rene de Graaf

General Counsel

Sander Schiereck

Industrial Deployment Manager

Zinaida Djodikromo

Senior Project Engineer

Robin Jongen

Build Director

Azd Zayoud

Head of R&D

Mahshad Yazdanipour

Senior Process Engineer

Frans Vollering

Finance Director

Karel Kraanen

Production Manager

Leslie Christiaansen

Finance manager

Supervisory Board

Our experienced board members bring a valuable perspective on governance and strategy.

Henning E. Jensen

Chairman & Independent Board Member

Michiel Kool

Vice chairman & Independent board member

Jan Willem Muller

Board Member

Boudewijn van Vliet

Board member